Quality & Safety

- Safe and Reliable Products

-

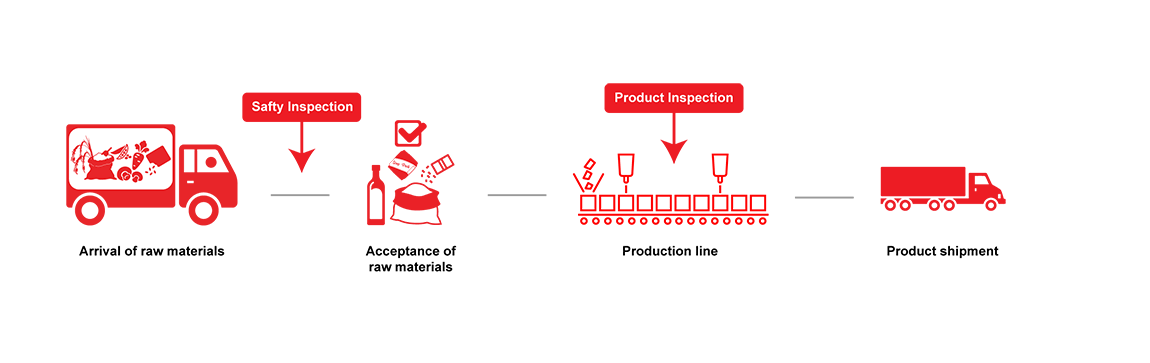

People love Sapporo Ichiban because of our reputation for safety and reliability. Sanyo Foods implements top-notch inspections throughout the production process and starting with raw materials.

- Choosing Reliable Ingredients

-

We strive to ensure quality and safety at all levels of production. To this end, we developed a raw material acceptance system and a production inspection process that each ingredient and product must go through before hitting shelves. We also strictly comply with all laws and regulations so our customers can always feel confident when putting Sapporo Ichiban on the table.

Ingredients

- Consumer Confidence: Our Top Priority

-

Our company’s safety standards prioritize consumer confidence. The first step in this process is carefully screening raw materials. Sanyo Foods meticulously analyzes all materials before they are delivered to our plant. We check for trans fat, allergens, etc. and ensure that we only obtain perfectly safe ingredients.

- Displaying Food Allergies

-

Based on thorough information from our raw material manufacturers, we list the exact contents on our packaging. We clearly display food allergy warnings for fish, shellfish, tree nuts and peanuts in accordance with FDA regulations.

- Raw Material Acceptance

-

Prior to accepting any raw materials, we process samples and conduct a thorough quality analysis. We retest to make sure that all materials meet applicable criteria. We regularly test all of our raw materials to ensure that any changes are immediately detected.

Production

- Safety is guaranteed through state-of-the-art facilities and human checks

-

At each Sanyo Foods factory, highly automated manufacturing lines are operated under total computer control. A variety of inspection and checking equipment is installed at each part of the production process to guarantee safety.

At the same time, employees are fully utilized to supplement the performance of our machines. Products are sampled multiple times a day for quality assurance. The contents and packing are also overseen by our well-trained employees. These advanced automated inspections coupled with human testing are our way of ensuring that consumers can rely on the safety and excellence of our products.

- Product Inspection

-

Using X-rays and other technology on the production line, we are able to weigh and inspect products for metal and foreign objects. Workers also conduct visual inspections. Moreover, we undertake sensory testing and analysis to ensure safety and quality.

- Traceability

-

Through the use of expirations dates and manufacturer plant ID codes, we can identify which factory our raw materials came from and when they were produced.

Research & Development

We test and retest in our Cooking and Development Room in order to achieve the best results. A team of 30 researchers and professional taste testers work with each product to achieve flavor perfection. These workers create a series of tests with the same goal in mind; creating the most delicious ramen possible.

Safety is the First Step when Making our Delectable Ramen

When making our ramen, we not only consider taste but safety as well. Delivering a safe and reliable product is of the upmost importance to our company. In order to meet our high safety standards, we individually wrap all of our products in high performance packaging to prevent quality decline.

We love hearing that people can’t get enough of our ramen. To provide the best possible taste, we conduct regular taste tests and are never satisfied with the status quo. While we understand the importance of taste consistency, we constantly strive for improvement. We appreciate our customer’s feedback and utilize it to develop the flavors of Sapporo Ichiban.